Platform grates

Home » Platform grates

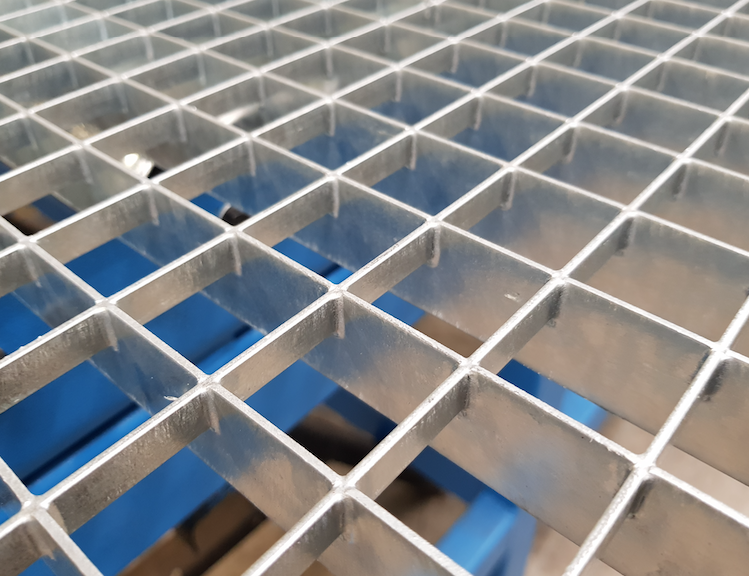

Platform grates – high quality and Polish production

According to customer requirements, WEMA gratings can be cut according to the indicated shapes, framed and with welded toe boards, strips and anti-slip angles (in accordance with customer documentation).

Read more about the products in our offer:

Side boards are a reinforced frame made of sheet metal that extends above the upper part of the grate. Most often, it serves as protection against the foot slipping off the grate.

The anti-slip strip is made of perforated angle. It is welded to the end bearing flat bar.

We offer galvanized or “black” – non-galvanized steel gratings.

Fixing platform gratings – our offer also includes holders for mounting platform gratings: standard, hook, double, universal, disc, etc.

Platform gratings - welded

Welded gratings – multifunctional and stable structures

Welded gratings are made of supporting flat bars and filling transverse bars. Load-bearing steel flat bars – unlike pressed gratings – are not previously cut to introduce transverse bars. In the process of automatic resistance welding, transverse bars are welded to supporting flat bars. This combination of both rods gives great stability to the entire structure. At the customer’s request, hot-dip galvanizing of the welded grating is possible.

The gratings we produce can have various shapes, according to customer requirements. They are used in various areas of industry and everyday life. Welded grating is suitable for: platforms, footbridges, ramps/exits, platforms, bridges, landings, balustrades, stairs, safety grilles, etc.

We use high-quality steel, so our wires and round drawn bars can be used universally wherever precision is required (screws, anchors, etc.). We deliver round drawn wires and bars in plain or softened condition. We take into account all technical requirements and specifications provided by customers.

Welded gratings, just like pressed gratings, can be used both outside and inside buildings.

- Our gratings can have a mesh (typical spacing of flat bars): 34 x 38 mm (and combinations of these dimensions).

- The following dimensions are used as the load-bearing flat bar: 25×2 mm, 25×3 mm, 30×2 mm, 30×3 mm, 40×2 mm, 40×3 mm, 40×4 mm.

- The transverse rod is a grooved rod with a diameter of 4.8 – 5.2 mm.

- The standard material used is S235JR black steel. The grates have frames according to the customer’s requirements.

Maximum dimensions of welded grating: 6100×1000 mm.

Our gratings – according to the customer’s requirements – can be hot-dip galvanized, which makes them resistant to weather conditions. Galvanized welded gratings are well protected against corrosion and UV radiation.

The grooved crossbar also provides an anti-slip effect. In addition to full gratings, we also produce landing steps (stairs) made using this technique.

Platform gratings - pressed (smooth or anti-slip)

Push-in (also known as pressed) cards can be used both outside and inside buildings.

- Our gratings can have a mesh (spacing of flat bars): 11.11 mm; 22.22mm 33.33mm; 44.44mm; 55.55 mm and 66.66 mm (and combinations of these dimensions).

- The following dimensions are used as the load-bearing flat bar: 25×2 mm, 25×3 mm, 30×2 mm, 30×3 mm, 40×2 mm, 40×3 mm, 40×4 mm.

- A transverse flat bar is a flat bar with dimensions: minimum 9×1.8 mm and maximum 15×1.8 mm.

The standard material used is S235JR black steel. The grating can have borders according to the customer’s requirements.

Maximum dimensions of the press-in grating: 4000×1500 mm.

In addition to full pressed gratings, we also produce landing steps (stairs) made using the pressed technique.

Our offer also includes push-in anti-slip platform gratings. The flat bars used in them are subjected to the serrate process, i.e. cutting the edges of the flat bar into characteristic teeth, which increase friction and reduce the likelihood of slipping.

Our offer includes, among others: seratized gratings with supporting flat bar 30×2 mm (mesh 33×33, 33×11 mm and others), 30×3 mm (mesh 33×33, 33×11 mm and others), 40×2 mm (mesh 33×33, 33×11 mm and others), 40×3 mm (mesh 33×33, 33×11 mm and others), other).

Welded gratings – multifunctional and stable structures

Press-in gratings are made of load-bearing and transverse steel flat bars. The supporting flat bar is precisely cut and thus creates the so-called locks into which transverse flat bars are then pressed (ironed).

Our pressed gratings can be hot-dip galvanized, which makes them resistant to weather conditions. They can have different shapes and sizes, according to the customer’s requirement. Pressed gratings of this type are used in various areas of industry and everyday life: platforms, footbridges, balustrades, platforms, bridges, landings, ramps, stairs, safety grilles, etc.